Hydraulic and functional testing

Seize our broad experience with testing the most diverse properties of your products.

LIWO offers complex functional tests due to our experience with electrical, mechanical, magnetic, hydraulic or pneumatic series parts. In the process, different tests can also be combined each imbedded in proven systems concepts.

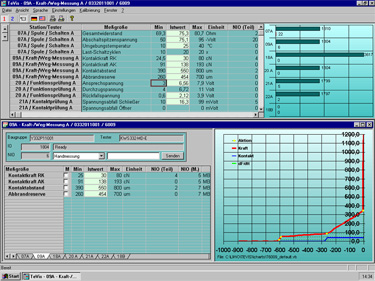

It is important during functional tests to subject test pieces to different input values within the demanded tolerances in a stable and supported way. In doing so the output values are checked to verify they are within the determined limits. Results are measurement points and characteristic curves and finally a good/bad statement.

LIWO software stores data and characteristic curves with test and time stamp in databases with the corresponding test piece and analyzes them statistically.

Our developer team with specialists from physics, mechanical engineering, electronics and software also solve extraordinary tasks. Put us to the test.

| Typical input values: |

|---|

| Controlled pressures of different gases and liquids |

| Electrical currents and voltages also with diverse signal forms such as |

| Ramps or pulse width modulations |

| Rotation speed |

| Force / displacement |

| Vacuum |

| Flow rate |

| Temperature |

| Flame |

| Typical dimensions: |

|---|

| Flow rates up to 120l per minute |

| Pressures or pressure curves from a few mbar to 1000 bar |

| Electric currents |

| Voltages |

| Resistances |

| Force / displacement |

| Torque |

| Temperature |

| Camera photos |

| More characteristics can be determined from a combination of measurement values and characteristic curves such as: |

|---|

| Switch times |

| Hysteresis |

| Switch separation |

| Gradients |

| Gradient changes |

| Resistance stability |

| Maintaining envelopes |

| Determination of forces and paths from electrical measurement values |