NID leak test - Cooperation with Gemtec

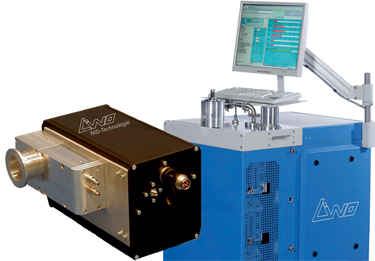

LIWO now expands its proven leak detection technologie by the forward-looking and compact automatic tester UNIDIM NID (NitrogenDensityDetection). Based on nitrogen UNIDIM NID provides clear benefits in times of scarce resources. The patented NID method is to market since October 2013.

Leaks are detected by measuring the change in Nitrogen concentration due to nitrogen molecules escaping from a test component that has been filled with air or nitrogen.

The UNIDIM NID enables the detection of leaks to 10-5 mbar l / s ( resolution 10-6 mbar l / s) that were traditionally only detectable with expensive tracer gas- or manual underwater test methods.

In fully automatic operation this leak detection system achieves reliable measurements even with short cycle time and also operator-independent.

Since the temperature due to the process does not influence the measurement process, the NID method yields even under harsh manufacturing conditions reliable results.

This is particulary true for plastic or elastic parts where temperature influences the production process or Heliumpermeation is considered.

Even sealed products, that previously had to be filled only by consuming bombing process with trace gas, can be tested for leaks reliably and fast with the UNIDM NID.

NID - Leak testing without trace gas

Field of application

Closed components filled with air

With no other method such components can be tested as accurately and as quickly for leaks.

Sealed parts, which previously had to be filled with the consuming and very slow bombing process can be tested quickly and reliably with this method. Excamples:

- Blister

- Vials

- Ampoules

- Carpules

- prefilled syringes binoculars

- Electronic housings

- Components

- ...

Components, which are previously be filled with test gas

The "test gas" air saves ressources and is not problematic in disposal.

Components, which are previously tested with air and pressure change method

If searching for smaller leaks with pressure change processes, the negativ effects caused by temperature and humidity are no longer economically manageable. The differential pressure method is by factor 100 less accurate than the method NID.